The filament spool roller on FLSUN SR 3d-printer (their base-model) is nothing more than a simple metal tray against which the spool will loudly overcome the friction and skid around.

Problem

- Factory provided spool roller is a metal tray causing noise and extruder imprecision.

- I don’t want to leave the house to get components for already available rollers on Thingiverse.

Opportunities

- Have 14mm OD, 8mm ID, 4mm high, sealed ball bearings on-hand.

- Have #10-24 bolts and hardware on-hand.

- Have a working 3D printer.

- Aching for a one evening project.

Design Process

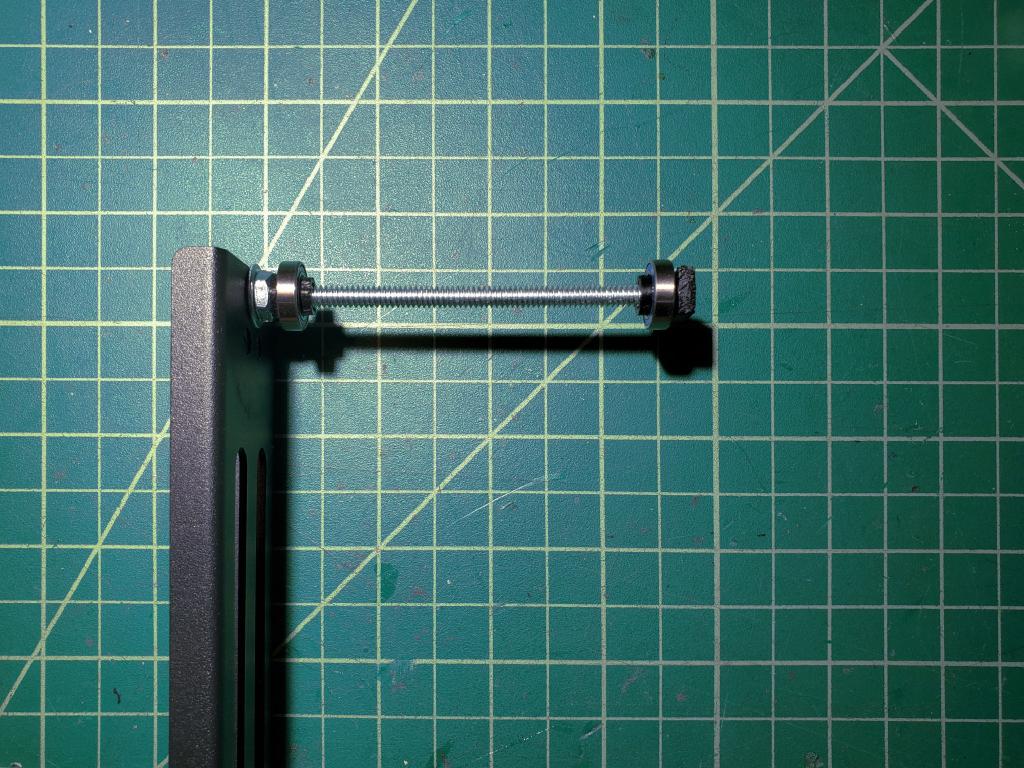

To maximally simplify the project, the vertical tray support was reused. It is made of high strength steel already sufficient for supporting a full spool of filament. Additionally, any modifications of this OEM part needed to allow for reverting to factory configuration in case of project failure.

As is true of many of my projects, I used composite1 construction.

Core of the design is a 3.5" #10-24 bolt acting as the axis for the roller. It is affixed to the vertical tray through a hole and secured using flat washers and a nut.

Overview

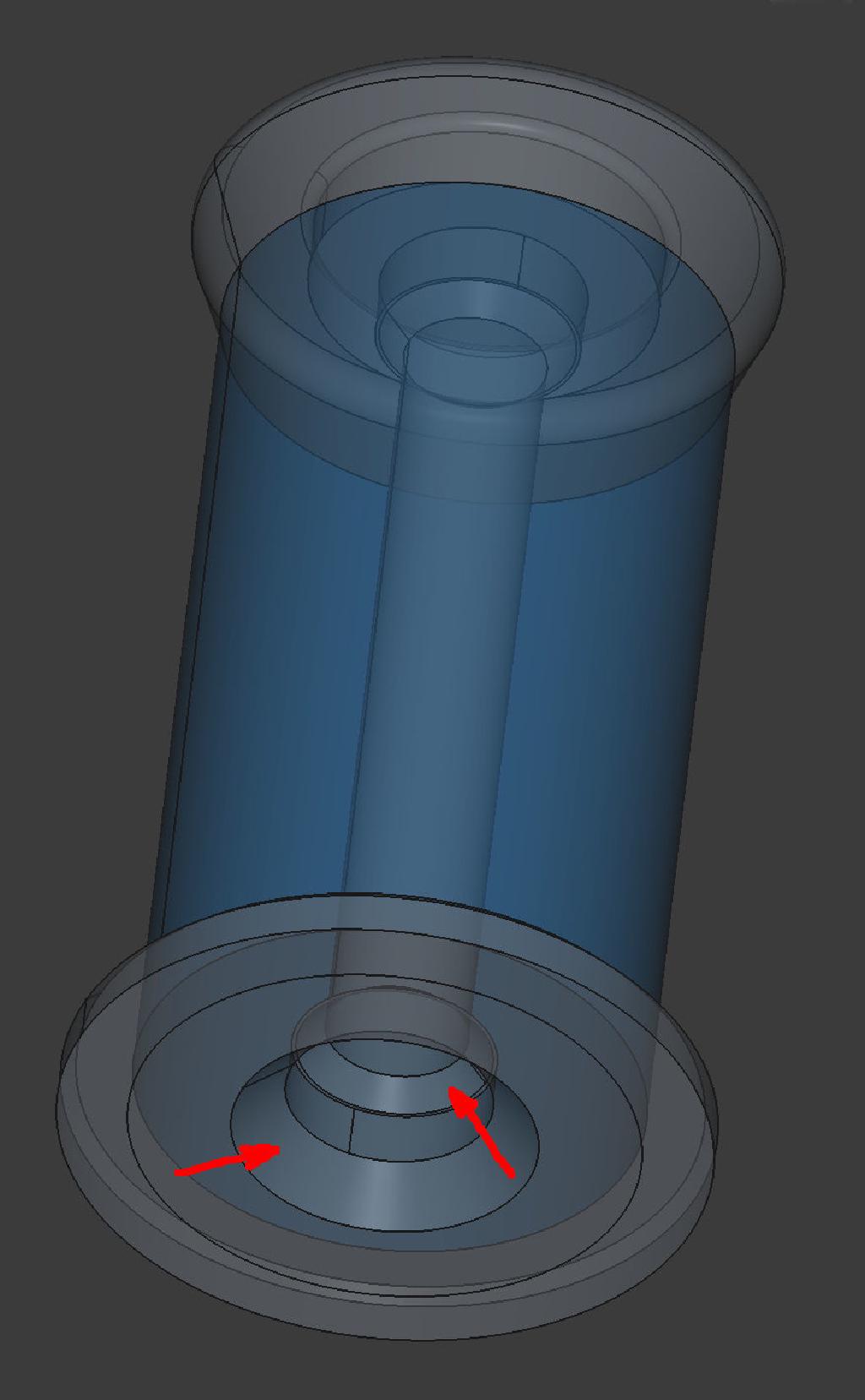

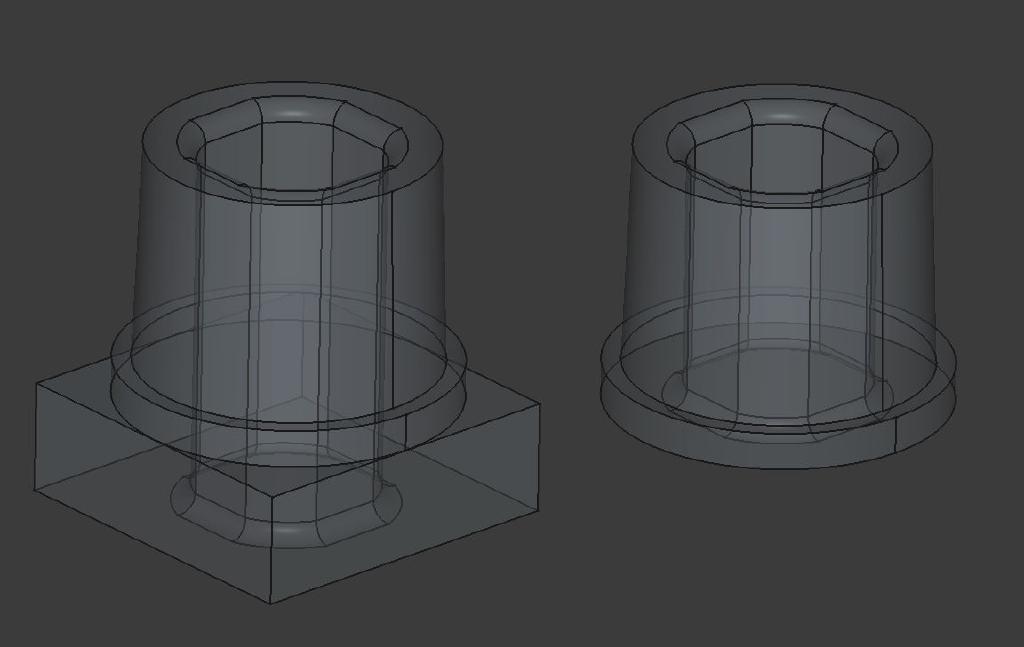

The spool is designed to be printed vertically without supports. To that end, all would-be unsupported horizontal faces are replaced with 45° faces. Note the two 45° tapers on bottom of the freecad model picture.

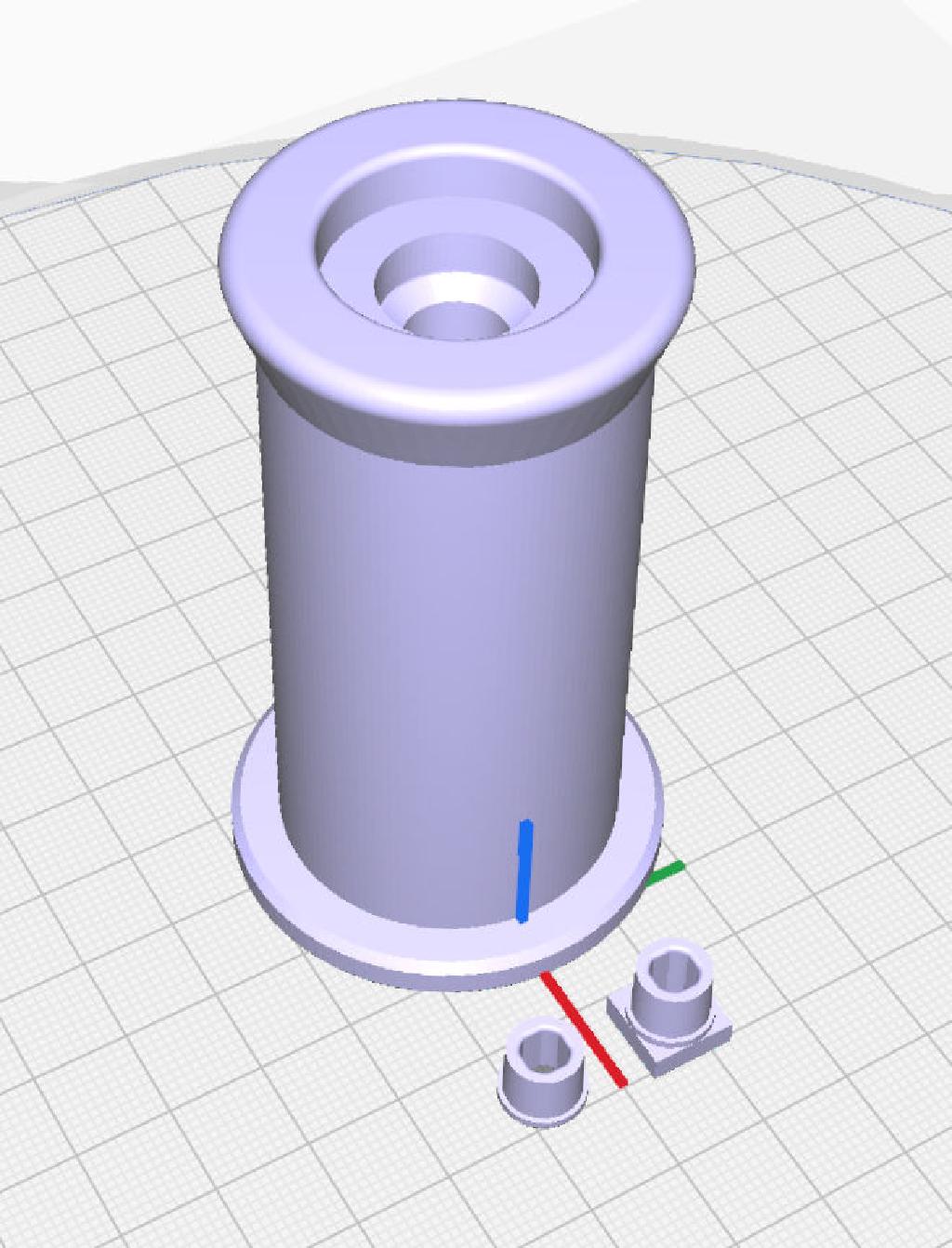

Two 3d printed bearing-holders are threaded onto the bolt. Ball bearings are then held captive on the bearing-holders by the main spool from inside and bearing-holder lips on the outside.

Note the out-of-round inner diameter of bearing-holders to provide material for the machine bolts to “self-tap” into the PLA.

Assembly

- drilling hole in the vertical tray

- #10-24 3 1/2" bolt

- washer on the bolt

- installing bolt+washer into the drilled vertical tray

- second washer

- nut

- self tapping the inner bearing-holder (with bearing) onto the bolt against the nut

- the 3d printed spool is then slid onto the inner-bearing

- self tapping the outer bearing-holder (with bearing) into the bolt against the spool

- this will hold the outer bearing in position in the spool

Summary

Using simple hardware, ball bearings and three 3d printed parts, I created a quiet, smooth and robust composite1 construction filament spool roller without leaving the house 😄.

If you have a FLSUN SR printer, or one which uses similar vertical tray to hold the filament spool, you can print my spool roller using these STL files. Thingiverse share.