Aircraft engines need to be protected from moisture to prevent internal corrosion. As their overhaul intervals often exceed 10 years and it is not uncommon for an engine to not operate for months at a time, protecting them from corrosion can significantly extend their operational life.

Ideas

Over the years, I studied both self-built and commercially available engine dehumidifiers. Of the self built designs, none resonated with me. After my engine overhaul, I didn’t have much money left over to afford a commercial unit, so instead, I came up with my own for under $100.

Design

I started with a commercially available, clear, airtight container with sealed lid. I added an off the shelf humidity and temperature battery powered sensor - which I glued to the inside of the lid. Between the sensor and desiccant turning dark when saturated with moisture, I have redundant indications of operation.

The container is large enough to hold 6lb of color-turning desiccant and an aquarium style air pump. I added two air-tight through the wall couplers - the bottom one with an air-stone is the air-intake and top one is for exhaust. Next I cut the power plug off the pump and ran the cable through the wall with an air-tight gland.

Filling the container with desiccant, placing the pump on the top and utilizing a fuel filter on the pump output, ensures clean dry air will be pumped to the engine. This design maximizes simplicity and does not require complex air-tight pump modification. Instead the entire container is sealed with pump inside and the pump can ONLY pump the dry air within.

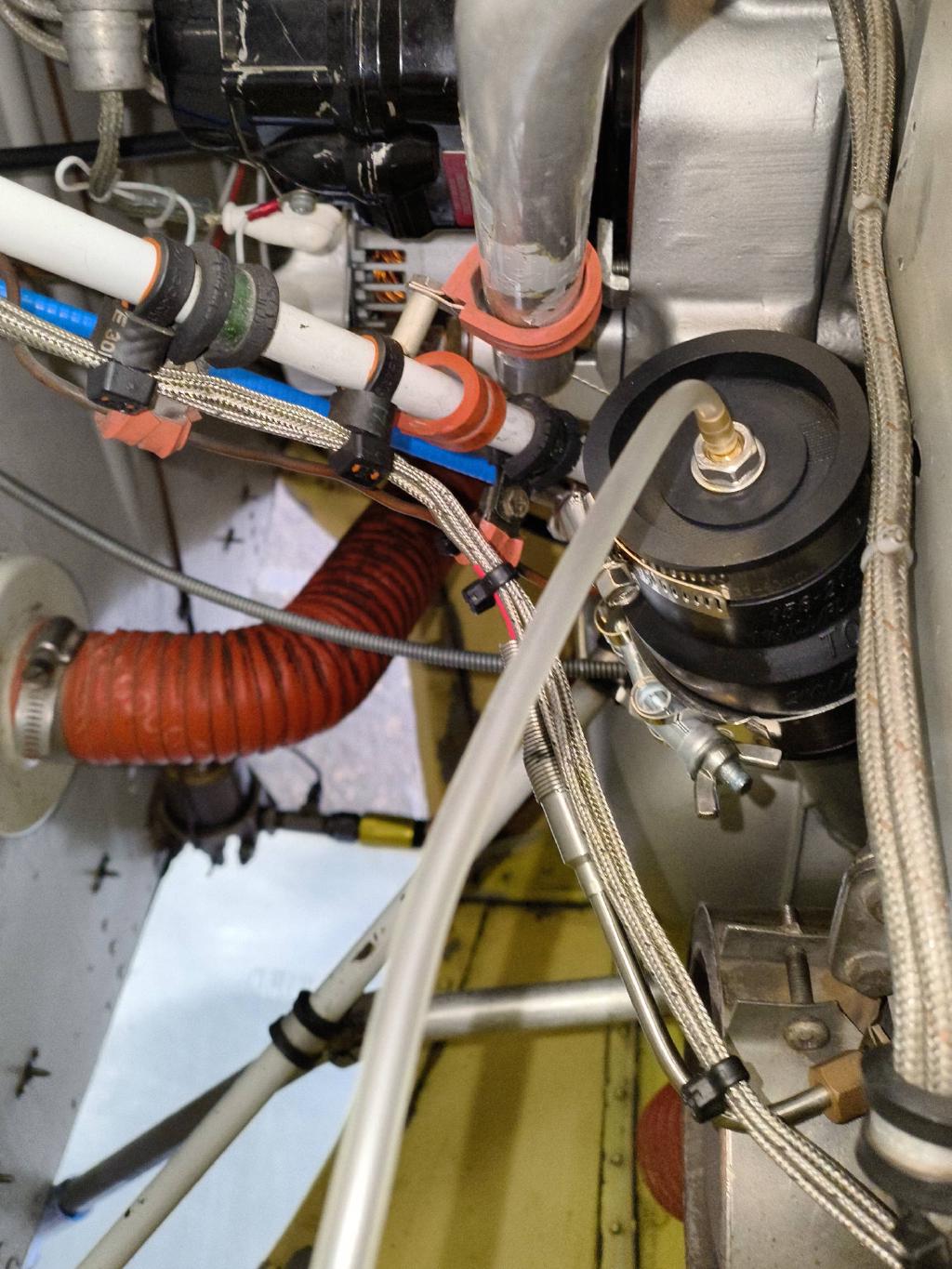

The oil filler neck on an O-200A is 2.25" OD, it is not threaded but does have a perfectly round outer diameter. I found a soft rubber pipe coupler for 2.25" to 2.0" pipes with nice 45 degree chamfer between the inside diameters, which will act as an additional sealing surface. I used a wide strap band with butterfly nut for easy adjustability for air-tight friction fit. The end was capped and a through coupler added.

To make this a closed loop system, I used 5/8" PVC pipe to extract engine air through the engine oil breather pipe. Once the engine is filled with dry-air, it only needs to periodically re-circulate this same air through the desiccant to remove any moisture which enters the engine due to daily temperature cycles.

Before the engine air can enter the desiccant pile, it is ran through an air-tight plastic jar which separates the oil and allows vacuum produced by the air pump inside the desiccant container, to draw from the engine.

Final piece of design is a simple 110V timer which is set to run at a fixed daily cycle to circulate the closed-loop dry air through the engine.

Testing

Using my lungs to push air into the engine through the desiccant pile tube, results in an audible air movement on the oil breather pick up tube. So far so good, but I’m capable of producing higher pressures than the aquarium pump.

Letting the pump push air to the engine, while plugging in the air intake of the desiccant container results in vacuum build-up and hissing when re-opened. The pump can definitely move air into engine (low air flow and low pressure)

Running it after a flight will confirm operation as hot moisture from oil breather tube will be observed moving into the separator (as will droplets of oil) and humidity read by the container sensor will get a bump until all moisture is recirculated and absorbed.

I will adjust the daily duty cycle to attain engine drying and maximize the desiccant life. Once the desiccant saturates with moisture it turns dark and needs to be baked to dry it and use it again and again. I expect at least two months between desiccant recycling.

Potential changes

If needed, this design allows for an easy upgrade to a higher pressure air pump (simple swap) and using a larger container with more desiccant for longer recycling intervals.

Summary

I added an affordable and simple engine dryer to my hangar for a fraction of the cost of commercial units. In 10+ years, when my engine it is overhauled again, I’ll learn how effective this effort was and if I get compliments how corrosion free the engine insides were :)